Manufacturing Industry Trends: 12 Key Developments Shaping 2025 and Beyond

Key takeaways

- The manufacturing industry is undergoing a digital transformation, with AI, IoT, and automation leading the way.

- The shift towards sustainable manufacturing and circular economies is gaining momentum in response to regulatory and consumer demands.

- Smart manufacturing and digital twins are revolutionizing production efficiency and predictive maintenance strategies.

- Cloud adoption and low-code platforms are improving collaboration and accelerating workflow automation across manufacturing enterprises.

The manufacturing industry is evolving rapidly, driven by technological advancements, automation, and increasing demand for efficiency. As industries embrace smart manufacturing and AI-powered solutions, businesses are optimizing production processes, reducing waste, and improving operational agility.

By 2025, digital transformation in manufacturing will redefine how companies design, produce, and deliver products. According to Deloitte, 76% of manufacturers have already begun implementing smart manufacturing initiatives, aiming to boost efficiency, enhance supply chain visibility, and reduce operational costs.

This blog explores the latest manufacturing industry trends and how emerging technologies such as artificial intelligence, digital twins, cloud computing, and process automation are shaping the industry’s future.

Table of Contents

Understanding the Role of Technology in the Manufacturing Industry

Technology plays a transformative role in modern manufacturing, enhancing productivity, streamlining workflows, and driving cost efficiency. As competition intensifies, manufacturers are adopting innovative solutions to stay ahead. Below are key areas where technology is making an impact:

- Process Automation & Robotics: AI-powered workflow automation reduces labor-intensive tasks, minimizes errors, and accelerates production cycles.

- Cloud Computing & Data Analytics: Manufacturers leverage cloud platforms for real-time collaboration, predictive analytics, and operational insights.

- Smart Factories & IoT: Connected devices enhance supply chain management and enable predictive maintenance to prevent equipment failures.

- Sustainable Manufacturing Practices: Industries are integrating eco-friendly processes, recycling materials, and reducing carbon footprints.

With digitalization accelerating across the sector, companies must embrace these technological advancements to remain competitive and meet future demands.

Top Manufacturing Industry Trends in 2025

As we approach 2025, the manufacturing industry continues to evolve rapidly, driven by emerging technologies and innovative practices. From automation to sustainability, these trends are set to redefine the future of manufacturing.

1. Workflow Management & Process Automation

Manufacturers are increasingly investing in workflow management and process automation to enhance efficiency and eliminate bottlenecks in production and logistics. Automated workflows help streamline operations by reducing manual approvals, minimizing production delays, and ensuring real-time tracking of resources. Predictive maintenance scheduling, which uses AI-driven insights to anticipate equipment failures before they occur, prevents costly downtimes and optimizes machine performance.

Additionally, real-time tracking systems ensure better inventory visibility, efficient order processing, and improved coordination between supply chain partners. By embracing workflow automation, manufacturing firms can reduce inefficiencies, lower costs, and improve overall productivity.

2. Business Process Management (BPM)

Business Process Management (BPM) is transforming manufacturing by ensuring that operations are optimized for efficiency, compliance, and cost reduction. BPM systems help manufacturers design, execute, monitor, and refine business workflows to improve operational agility. Companies are now integrating low-code BPM platforms to streamline supply chain coordination, automate inventory tracking, and enhance quality control processes.

With predictive analytics embedded in BPM solutions, manufacturers can identify inefficiencies and optimize production schedules. BPM tools also ensure seamless coordination between teams, suppliers, and logistics partners, reducing delays and improving supply chain efficiency.

3. Project Management in Manufacturing

Effective project management methodologies are crucial for manufacturers to ensure smooth execution, timely delivery, and cost control. AI-powered project tracking tools enable manufacturers to monitor production schedules, allocate resources efficiently, and predict potential project delays. Automated scheduling solutions synchronize production timelines with raw material availability and workforce scheduling, reducing project disruptions.

With the increasing complexity of modern manufacturing projects, companies are adopting Agile and Lean methodologies to optimize production lifecycles. By integrating real-time reporting and task automation, manufacturers can reduce inefficiencies and enhance overall project success rates.

4. Low-Code Platforms & Citizen Development

Low-code and citizen development platforms are gaining traction in the electrical manufacturing and automotive manufacturing sectors, allowing businesses to automate repetitive processes and create customized digital solutions without relying heavily on IT departments. These platforms empower non-technical employees to design, deploy, and manage applications for inventory control, production monitoring, and compliance tracking.

With drag-and-drop interfaces and pre-built automation templates, manufacturers can accelerate digital transformation efforts and streamline operations with minimal technical expertise. The adoption of low-code platforms enhances agility, improves process efficiency, and reduces reliance on expensive software development cycles.

5. Cloud Adoption & Data-Driven Manufacturing

The shift toward cloud-based platforms is revolutionizing manufacturing operations by providing real-time data access, improving collaboration, and enabling AI-powered analytics. Cloud computing reduces IT infrastructure costs, enhances scalability, and improves security, making it easier for manufacturers to manage global supply chains efficiently. Cloud-based AI solutions analyze production data in real time, identifying inefficiencies and suggesting optimizations.

Manufacturers leveraging cloud adoption benefit from seamless integration with IoT devices, automation platforms, and enterprise resource planning (ERP) systems, ensuring better operational transparency. Additionally, cloud computing enables remote access to manufacturing systems, facilitating remote monitoring and collaboration among global teams.

6. Enhanced Collaboration & Remote Monitoring

With distributed supply chains and a growing hybrid workforce, manufacturers are investing in collaborative digital tools and remote monitoring solutions to ensure seamless operations. Virtual inspections and real-time performance tracking allow manufacturers to maintain production quality without requiring physical presence. Smart factories are leveraging IoT-powered sensors and AI-driven analytics to monitor equipment health, detect anomalies, and optimize performance.

Collaborative tools such as cloud-based dashboards, shared data repositories, and remote troubleshooting platforms enhance communication among teams, vendors, and suppliers. This trend enables manufacturers to adapt to global disruptions, improve operational efficiency, and ensure business continuity in a rapidly evolving industry.

7. Analytics and Big Data Utilization

The integration of big data and AI-driven analytics in manufacturing offers a wealth of insights into operations, enabling manufacturers to optimize supply chain efficiency, improve production scheduling, and forecast customer demand more accurately. By utilizing predictive analytics, companies can proactively manage inventory levels, ensuring that stock is replenished based on actual demand rather than projections alone.

Furthermore, manufacturers can predict and prevent machine failures by analyzing historical performance data, thereby reducing downtime and maintenance costs. AI-driven insights into production trends also help businesses identify bottlenecks, optimize workflows, and make smarter, data-backed decisions, increasing operational efficiency.

8. Smart Manufacturing & IoT Integration

Smart manufacturing powered by IoT is revolutionizing the way factories operate. By integrating real-time sensors, connected machinery, and automation software, manufacturers can gather valuable data to enhance operational processes. IoT-enabled factories enable predictive maintenance, reducing production downtime by identifying potential machine failures before they occur. The ability to monitor machinery performance in real-time also improves efficiency, as manufacturers can quickly address operational issues and adjust production schedules.

Furthermore, IoT devices optimize energy usage by monitoring power consumption, ensuring that manufacturing processes are both cost-effective and environmentally sustainable. This holistic approach to connected manufacturing enables enhanced productivity and operational excellence.

9. Sustainable Circular Economy

As sustainability becomes a key priority in the manufacturing sector, companies are increasingly adopting circular economy principles. The circular economy focuses on reducing waste, reusing materials, and ensuring that resources are efficiently utilized throughout the lifecycle of products. Manufacturers are investing in recyclable materials and improving production techniques to minimize waste generation.

Additionally, energy-efficient production models are being integrated into manufacturing processes to reduce environmental impact. Manufacturers are also adopting eco-friendly logistics and sustainable packaging to minimize the carbon footprint of their products. By focusing on these sustainable practices, companies can reduce environmental harm while driving innovation and meeting the growing demand for eco-conscious products.

10. Generative AI and Advanced Data Utilization

Generative AI is reshaping product design and manufacturing automation by creating new prototypes, optimizing workflows, and enhancing decision-making processes. In manufacturing, generative AI is used to simulate designs, reducing the time and cost traditionally required for physical prototyping. The technology also allows for continuous improvement in product development by analyzing vast amounts of data to propose optimized solutions.

Additionally, generative AI enhances quality control by using advanced algorithms to detect defects in products before they reach the consumer. This use of AI not only improves manufacturing efficiency but also enables businesses to offer better-quality products to the market while reducing waste.

11. Artificial Intelligence and Virtual Processes

AI-driven virtual processes are increasingly being used in manufacturing to improve simulation-based testing, defect analysis, and real-time monitoring of production activities. AI-powered software helps manufacturers predict machine failures by analyzing patterns and performance data, ensuring that equipment is properly maintained and production cycles are optimized.

In addition, AI enhances real-time production monitoring, allowing for quick identification of issues that may disrupt the manufacturing process. With AI tools integrated into workflows, manufacturers can enhance operational agility, adapt to unforeseen circumstances more effectively, and improve production timelines. This allows businesses to stay competitive by improving both quality and efficiency in production.

12. Digital Twins for Manufacturing Optimization

Digital twin technology creates virtual replicas of physical assets, such as machines, production lines, or entire factories, enabling businesses to simulate, monitor, and optimize manufacturing processes. By having a virtual model of their physical assets, manufacturers can test new configurations and process improvements before making changes in the real world. This reduces the risks of expensive mistakes during implementation.

Furthermore, digital twins play a critical role in predictive maintenance, as they can analyze data from physical assets to anticipate failures before they happen, lowering maintenance costs and preventing downtime. The technology also enhances product quality control, as manufacturers can analyze how real-world conditions affect production processes and adjust accordingly. Additionally, digital twins improve supply chain logistics by providing real-time tracking, enabling more accurate forecasting and optimizing inventory levels based on actual demand rather than estimates.

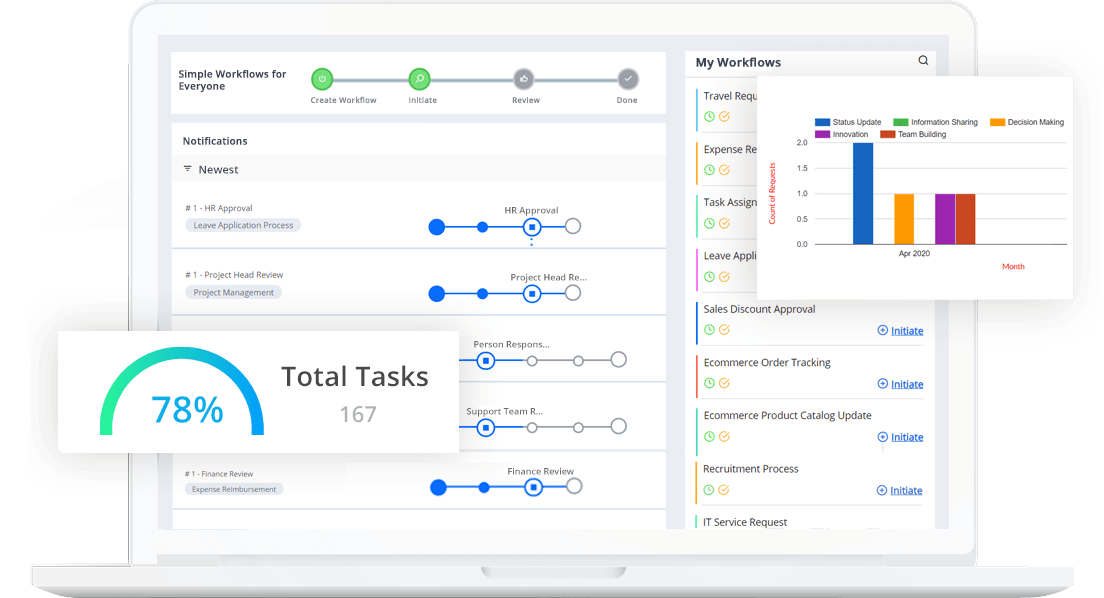

End-to-end workflow automation

Build fully-customizable, no code process workflows in a jiffy.

Strengthen Your Manufacturing Operations with Cflow’s No-Code Solution

Cflow is a no-code workflow automation solution that streamlines manufacturing processes, improves collaboration, and enhances operational efficiency. By automating approval workflows, inventory tracking, and quality assurance, Cflow empowers manufacturing teams with seamless process management.

How Cflow Enhances Manufacturing Workflow Efficiency –

- AI-Powered Workflow Automation – Cflow automates approval processes, inventory management, and order tracking, ensuring seamless operations and reducing manual intervention in manufacturing workflows.

- Seamless System Integration – The platform connects with ERP systems, cloud storage, and IoT platforms, enabling real-time data synchronization and improved visibility across the entire production process.

- Advanced Analytics & Reporting – Cflow provides predictive insights that help manufacturers optimize supply chain management, enhance production efficiency, and reduce operational bottlenecks.

- Customizable No-Code Workflows – With its intuitive no-code interface, Cflow allows manufacturers to design and implement automated workflows that align with their specific operational requirements.

- Secure and Scalable Solutions – Cflow ensures robust data protection, regulatory compliance, and enterprise scalability, making it a reliable automation tool for manufacturers of all sizes.

Final Thoughts

The manufacturing industry is undergoing a technological revolution, with AI, IoT, cloud computing, and automation driving efficiency and innovation. Companies that embrace digital transformation will gain a competitive advantage, reduce costs, improve productivity, and achieve sustainable growth. Embracing these advancements ensures a more agile and responsive business model.

Ready to optimize your manufacturing operations with automation? Sign up and try Cflow today and accelerate your digital transformation to stay ahead of the competition!

FAQs

- What are the biggest technology trends in manufacturing?

The most significant trends include AI-driven automation, IoT-powered smart factories, cloud computing, digital twins, and advanced analytics. These innovations enhance efficiency, reduce costs, and improve decision-making in manufacturing.

- Why is workflow automation essential in the manufacturing industry?

Workflow automation eliminates manual inefficiencies, improves production timelines, and enhances collaboration. It also helps manufacturers streamline quality control, compliance tracking, and inventory management with real-time process monitoring.

- How can AI improve manufacturing processes?

AI enhances predictive maintenance, defect detection, and demand forecasting in manufacturing. It also optimizes supply chain operations, automates production workflows, and improves resource allocation for better operational efficiency.

What should you do next?

Thanks for reading till the end. Here are 3 ways we can help you automate your business:

Do better workflow automation with Cflow

Create workflows with multiple steps, parallel reviewals. auto approvals, public forms, etc. to save time and cost.

Talk to a workflow expert

Get a 30-min. free consultation with our Workflow expert to optimize your daily tasks.

Get smarter with our workflow resources

Explore our workflow automation blogs, ebooks, and other resources to master workflow automation.

What would you like to do next?

Automate your workflows with our Cflow experts.