Oil and Gas Industry Technology Trends for 2025: How Technology is Reshaping the Energy Sector

Key takeaways

- The oil and gas industry is rapidly adopting digital technologies to improve efficiency, reduce costs, and enhance safety.

- AI, IoT, RPA, and digital twins are driving exploration, drilling, and refining automation.

- Cloud computing and edge computing enable real-time data processing and remote asset management.

- Blockchain, AR/VR, and advanced robotics are revolutionizing operations and security in the energy sector.

Introduction

The oil and gas industry is undergoing a major transformation driven by technological advancements and digitalization. With the increasing demand for energy efficiency, sustainability, and cost optimization, companies are leveraging automation, artificial intelligence (AI), and the Internet of Things (IoT) to improve operational workflows and decision-making.

According to Technavio’s market forecast, the digital transformation market in the oil and gas industry is expected to increase by USD 56.4 billion and grow at a CAGR of 14.5% between 2025 and 2029. Companies that embrace automation and digital solutions are expected to gain a competitive edge, ensuring efficiency, scalability, and enhanced safety.

This article explores the latest technology trends in the oil and gas industry, focusing on how technology is reshaping operations in exploration, production, refining, and supply chain management.

Table of Contents

Understanding the Role of Technology in the Oil and Gas Industry

Technology has played a crucial role in shaping the oil and gas sector, enabling companies to optimize operations, reduce downtime, and enhance productivity. Key innovations have transformed traditional methods in drilling, refining, and distribution by integrating data-driven decision-making and automation.

The adoption of automation and AI-driven insights allows companies to analyze large volumes of geological and operational data, leading to more accurate exploration and production planning. With IoT sensors, real-time monitoring, and digital twins, companies can ensure proactive maintenance and minimize equipment failures.

By implementing no-code automation platforms, oil and gas companies can streamline workflows, reduce manual intervention, and improve collaboration across departments. From field operations to asset management, technology is driving unprecedented cost savings and efficiency improvements.

Top Technology Trends in the Oil and Gas Industry

Innovations are reshaping traditional workflows, improving decision-making, and enabling real-time monitoring of assets. As sustainability and operational resilience become key priorities, adopting advanced technologies is essential for staying competitive in a dynamic market. The following trends highlight the most significant technological advancements shaping the future of the oil and gas industry.

1. Robotic Process Automation (RPA)

Robotic Process Automation (RPA) is revolutionizing oil and gas operations by automating time-consuming and repetitive tasks. From data entry and compliance tracking to supply chain monitoring, RPA ensures faster processing, reduces human intervention, and minimizes errors. By integrating RPA into daily workflows, companies can streamline logistics, procurement, and administrative functions, leading to cost savings and improved efficiency.

- Reduces Errors– Implementing automation in acquisition processes has led to a 95% reduction in errors and streamlined data management.

- Improves Operational Efficiency – RPA speeds up document processing, inventory tracking, and procurement approvals, ensuring seamless business operations.

- Eliminates Human Errors – Automating compliance checks and regulatory reporting reduces data inaccuracies and ensures adherence to industry standards.

2. Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML technologies are playing a crucial role in predictive maintenance, risk assessment, and operational efficiency in the oil and gas sector. By leveraging AI-driven analytics, companies can make informed decisions, prevent costly failures, and enhance resource management.

- Reduces Downtime – McKinsey states that predictive maintenance can decrease machine uptime by 20% to 40%, translating into significant productivity gains.

- Enhances Exploration & Drilling – ML algorithms analyze seismic data to optimize reservoir modeling and drilling strategies.

- Improves Customer Support – AI-driven chatbots and virtual assistants streamline service requests, ensuring faster response times and improved operational efficiency.

3. No-Code and Low-Code App Development

No-code and low-code platforms enable oil and gas companies to develop automation workflows and applications without extensive coding expertise. These platforms provide an intuitive interface for automating asset tracking, maintenance scheduling, and workflow approvals, reducing development costs and accelerating deployment.

- Speeds Up Workflow Automation – Reduces development time for operational tools, allowing companies to automate approval processes and field operations quickly.

- Empowers Non-Technical Teams – Enables employees without programming skills to design and deploy custom applications for field management.

- Enhances Scalability – Supports the rapid expansion of automation solutions as business needs evolve.

4. Internet of Things (IoT)

IoT technology is transforming the oil and gas sector by enabling real-time monitoring of equipment, pipelines, and remote assets. Smart sensors collect and analyze operational data, helping companies optimize production, reduce risks, and enhance predictive maintenance.

- Enhances Equipment Maintenance – IoT sensors detect early signs of wear and tear, preventing costly equipment failures and downtime.

- Improves Remote Asset Monitoring – Companies can track pipeline integrity, offshore drilling operations, and storage conditions without needing physical inspections.

- Reduces Operational Costs – According to McKinsey, companies can reduce maintenance costs by 40%, and cut downtime by up to 50%

5. Process Automation in Refining & Production

Automating refining and production processes leads to increased efficiency, improved product quality, and reduced environmental impact. AI-powered automation ensures real-time optimization of refinery operations and enhances safety compliance.

- Optimizes Energy Consumption – AI-driven workflow automation solutions are helping refineries reduce energy consumption by 10%, lowering operational costs.

- Improves Production Yield – Automated control systems optimize chemical processing, ensuring maximum output while reducing waste.

- Ensures Compliance & Safety – Real-time monitoring of emissions, process deviations, and regulatory adherence enhances environmental sustainability.

6. Cloud-Based Automation Solutions

Cloud-based is driving innovation in the oil and gas industry by enabling seamless collaboration, centralized data management, and scalable automation solutions. Companies leverage cloud-based platforms to streamline operations and enhance decision-making.

- Facilitates Remote Team Collaboration – Cloud-based solutions enable real-time access to operational data, improving efficiency across multiple locations.

- Enhances Disaster Recovery – Automated cloud backups ensure business continuity by protecting critical operational data.

- Supports Scalability & Cost Efficiency –The majority of energy companies are shifting to cloud platforms to reduce IT infrastructure costs and improve scalability.

By integrating these automation-driven technologies, the oil and gas sector is enhancing productivity, minimizing risks, and ensuring long-term sustainability in a competitive global market.

7. Cloud Computing and Edge Computing

Cloud computing and edge computing are transforming the oil and gas industry by improving data processing capabilities, enhancing security, and enabling real-time decision-making. Traditional cloud computing allows oil and gas companies to centralize data storage, facilitate remote collaboration, and enhance disaster recovery planning. Meanwhile, edge computing ensures that data processing occurs closer to the source, whether at offshore drilling sites, refineries, or pipeline stations, reducing latency and improving responsiveness.

- Reduces Data Transmission Costs – Offshore drilling operations generate vast amounts of data. Edge computing processes this data on-site, reducing the need for constant cloud communication and lowering transmission costs.

- Enables Real-Time Analytics – Field operations in remote locations benefit from edge computing, as it enables instant processing of data, allowing for real-time decision-making without delays.

- Enhances Cybersecurity and Data Protection – Decentralized edge computing reduces the risk of cyber threats by preventing single points of failure. Sensitive operational data is processed locally, limiting exposure to external cyberattacks.

8. Blockchain Technology

Blockchain is revolutionizing oil and gas supply chains by providing an immutable, transparent, and secure digital ledger for recording transactions, contracts, and asset movements. The oil and gas industry is often plagued by contract disputes, regulatory compliance challenges, and fraud. Blockchain technology addresses these issues by creating a tamper-proof, verifiable record of every transaction.

- Reduces Fraud and Contract Disputes – By using smart contracts and blockchain-ledger verification, companies can reduce fraud in crude oil transactions and resolve contract disputes more efficiently.

- Enhances Asset Tracking – Blockchain ensures real-time visibility into oil logistics, tracking shipments, storage conditions, and transit routes, reducing inefficiencies in the supply chain.

- Ensures Compliance with Regulations – Regulatory authorities can use blockchain to monitor compliance with environmental and safety regulations, as companies have an auditable, unalterable record of operational data.

9. Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies are revolutionizing how oil and gas companies train employees, conduct inspections, and manage field operations. By simulating real-world scenarios, these technologies enhance worker safety, reduce training costs, and improve operational efficiency.

- Reduces Training Costs – VR-based training programs allow new employees to undergo interactive, hands-on training without requiring physical equipment. Companies witness a 75% decrease in training time, reducing sessions from 8 hours to 2 hours, resulting in substantial financial savings.

- Enhances Safety Training – AR/VR simulations allow workers to practice emergency scenarios, such as equipment malfunctions or hazardous material spills, in a controlled environment, reducing workplace accidents.

- Provides Immersive Site Tours – Oil companies use AR/VR for virtual site inspections and investor presentations, allowing stakeholders to explore offshore rigs, drilling stations, and refineries remotely.

10. Advanced Analytics and Big Data

The oil and gas sector generates an enormous volume of data from exploration, drilling, refining, and logistics. Advanced analytics and big data enable companies to extract valuable insights from this information, improving decision-making and operational efficiency.

- Predicts Oil Price Fluctuations – Big data analytics aggregates global economic, political, and market conditions to forecast oil price trends, helping companies make informed trading and investment decisions.

- Maximizes Extraction Efficiency – By analyzing seismic and drilling data, big data tools can optimize well placement, drilling parameters, and production rates, ensuring higher efficiency in oil extraction.

- Improves Supply Chain Management – Oil and gas companies use big data to analyze transportation routes, inventory levels, and supplier performance, streamlining logistics and reducing operational costs.

11. Digital Twins

Digital twin technology allows oil and gas companies to create virtual replicas of physical assets, including drilling rigs, pipelines, and refineries. By simulating real-world conditions, digital twins enable predictive maintenance, process optimization, and risk assessment.

- Improves Predictive Maintenance – Digital twins monitor equipment performance in real-time, identifying potential failures before they occur, and reducing downtime and maintenance costs.

- Reduces Operational Risks – Companies use digital twins to simulate different failure scenarios, allowing engineers to proactively adjust processes and mitigate risks before they impact operations.

- Enhances Drilling Precision – By integrating AI with digital twin models, oil companies can optimize drilling techniques, maximize resource extraction, and ensure efficient reservoir management.

12. Advanced Robotics

Robotics is playing an increasingly crucial role in automating hazardous and labor-intensive tasks within the oil and gas industry. From drilling operations to pipeline inspections, robotics improves efficiency, reduces human exposure to dangerous environments, and minimizes operational risks.

- Reduces Worker Exposure – Autonomous robots perform inspections in high-risk environments, such as deep-sea drilling sites and confined refinery spaces, reducing the need for human intervention in dangerous conditions.

- Improves Efficiency in Pipeline Inspections – Drones and robotic crawlers conduct real-time inspections of pipelines, detecting leaks, corrosion, and structural weaknesses with greater accuracy and speed than manual inspections.

- Enhances Precision in Drilling Operations – AI-driven robotic drilling systems increase the accuracy and efficiency of drilling processes, reducing material waste and optimizing oil recovery rates.

By embracing these emerging technologies, the oil and gas industry can enhance efficiency, reduce costs, and improve environmental sustainability while ensuring long-term resilience in a rapidly evolving energy landscape.

End-to-end workflow automation

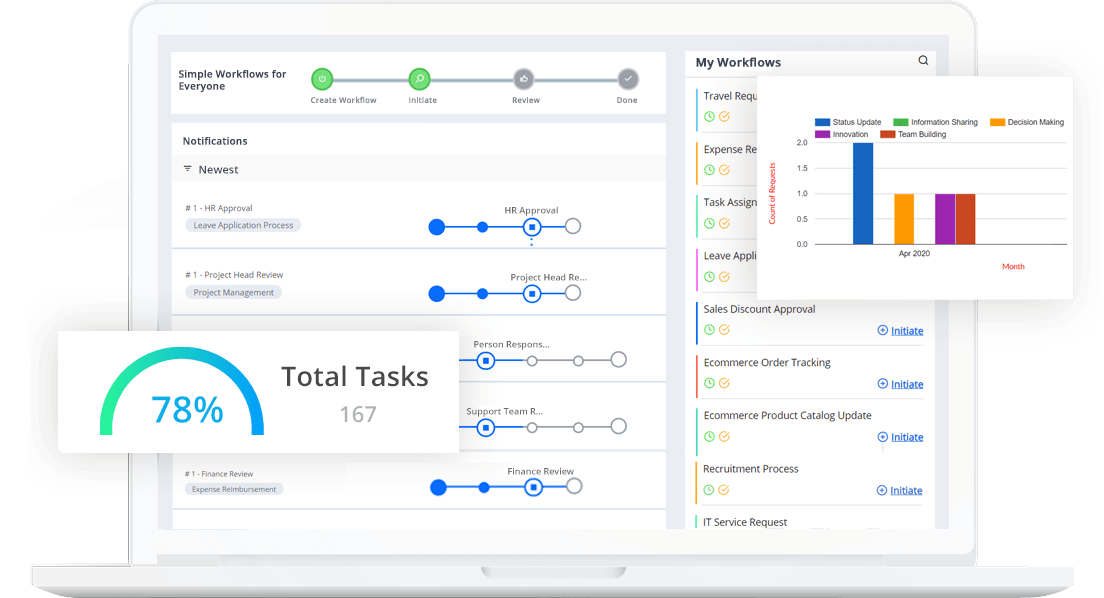

Build fully-customizable, no code process workflows in a jiffy.

Fortify Your Oil and Gas Business with Cflow’s No-Code Platform

Cflow is an AI-based, no-code workflow automation platform built to streamline and optimize critical processes in the oil and gas industry. With increasing digital transformation in the energy sector, companies require efficient, automated solutions to manage approvals, asset tracking, compliance, and operational workflows seamlessly. Cflow empowers organizations to eliminate manual inefficiencies, improve collaboration across departments, and accelerate decision-making with real-time insights.

How Cflow Enhances Oil & Gas Operations

- AI-Powered Workflow Automation: This tool Automates manual approvals, compliance tracking, and asset management by leveraging AI-driven insights. It ensures faster decision-making and reduced operational risks.

- Seamless Integration with Industry Tools – Cflow integrates with ERP systems, IoT sensors, cloud-based platforms, and field management software, ensuring real-time data synchronization and workflow consistency.

- Real-Time Monitoring & Reporting – Enables live tracking of operational activities, offering performance dashboards, predictive maintenance alerts, and automated reporting, helping teams proactively manage risks and optimize efficiency.

- Customizable No-Code Workflows – With drag-and-drop workflow builders, companies can create, modify, and deploy automated workflows without coding, adapting to changing business needs effortlessly.

- Scalable & Secure Solutions – Cflow ensures enterprise-grade security, compliance with regulatory standards, and scalability, making it the perfect solution for both large-scale enterprises and mid-sized energy companies.

By integrating Cflow into oil & gas operations, businesses can boost efficiency, ensure seamless coordination, and maximize productivity, ultimately enhancing profitability in a competitive industry.

Final Thoughts

Technology is transforming the oil and gas industry, driving automation, efficiency, and cost savings. Companies that leverage AI, RPA, IoT, and cloud-based solutions can optimize operations, enhance safety, and reduce downtime. By embracing digital transformation, oil and gas businesses can stay competitive in a rapidly evolving energy sector while ensuring compliance and sustainability.

Want to streamline oil & gas operations with automation? Sign up on Cflow today and revolutionize your workflow efficiency with intelligent process automation.

FAQs

1. How is automation impacting the oil and gas industry?

Automation is revolutionizing the oil and gas sector by enhancing safety, reducing operational costs, and improving asset monitoring. By eliminating manual inefficiencies, companies can streamline drilling operations, manage refineries efficiently, and automate compliance tracking. Robotics, IoT sensors, and AI-driven analytics further improve process accuracy and reduce human error, leading to safer, cost-effective, and optimized operations.

2. What role does AI play in oil & gas operations?

AI plays a crucial role in predictive maintenance, drilling optimization, and refining processes. It enables real-time monitoring of equipment health, reducing downtime and extending asset life cycles. AI-powered automation also enhances supply chain management, detects anomalies in pipeline operations, and supports energy efficiency goals, making oil & gas operations more sustainable and data-driven.

3. Why is no-code automation essential for oil companies?

No-code automation platforms enable oil and gas companies to rapidly automate workflows without extensive coding expertise. This reduces development costs, enhances scalability, and accelerates digital transformation. Companies can build and customize approval processes, automate field operations, and integrate industry-specific tools, ensuring faster decision-making and improved operational agility. No-code solutions also help businesses adapt quickly to regulatory changes and industry demands.

What should you do next?

Thanks for reading till the end. Here are 3 ways we can help you automate your business:

Do better workflow automation with Cflow

Create workflows with multiple steps, parallel reviewals. auto approvals, public forms, etc. to save time and cost.

Talk to a workflow expert

Get a 30-min. free consultation with our Workflow expert to optimize your daily tasks.

Get smarter with our workflow resources

Explore our workflow automation blogs, ebooks, and other resources to master workflow automation.

What would you like to do next?

Automate your workflows with our Cflow experts.