Inventory Management Software – What it is and Why Do You Need it?

Key takeaways

- Inventory management software helps businesses efficiently track, manage, and control inventory levels, reducing errors and improving operations. With real-time tracking and automation, businesses can minimize manual intervention and enhance stock accuracy.

- Using the best inventory management software enhances accuracy, prevents overstocking, and ensures seamless supply chain management. It also helps businesses optimize stock levels, improve order fulfillment, and avoid product wastage.

- Features such as automation, real-time tracking, and integration with other business systems make inventory mgmt software essential for modern businesses. Advanced analytics and AI-driven forecasting further help in making data-driven decisions.

- Choosing the right software for inventory management depends on business size, industry requirements, and specific functionalities needed. Factors such as scalability, ease of use, integration capabilities, and mobile accessibility play a key role in selection.

- Cflow offers a comprehensive inventory management solution with automation, real-time updates, and seamless workflow integration. The software ensures efficient procurement management, order tracking, and approval processes.

- Implementing inventory software management leads to cost savings, improved efficiency, and better decision-making through analytics and reporting. Businesses can streamline operations, reduce errors, and gain complete control over inventory.

Effective inventory management is critical for businesses to maintain profitability and ensure smooth operations. Inventory management software plays a key role in tracking stock levels, processing orders, and integrating with supply chain management systems. Whether a business operates in retail, manufacturing, healthcare, or e-commerce, using the best inventory management software helps minimize waste, optimize inventory levels, and increase overall efficiency.

One of the biggest challenges businesses face is maintaining accurate stock levels while preventing overstocking and understocking. Inventory software management allows businesses to automate stock control, track orders in real time, and streamline warehouse operations. This software eliminates manual errors and enhances decision-making through data analytics and reporting.

With the increasing complexity of supply chains, businesses must invest in reliable inventory mgmt software to prevent stock discrepancies, reduce operational costs, and improve customer satisfaction. This blog will explore the meaning, functions, and benefits of inventory software management, along with a detailed guide on choosing the right system for your business. Additionally, we will discuss how Cflow automates inventory management and the latest trends shaping the industry.

Table of Contents

What is Inventory Management Software?

Inventory management software is a digital tool designed to help businesses track, store, and manage stock levels efficiently. It enables companies to automate inventory tracking, reduce human errors, and optimize order processing. By integrating with other business systems such as Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM), inventory mgmt software ensures seamless workflow management.

Key capabilities of inventory management software include:

- Real-time inventory tracking to prevent stock discrepancies.

- Automated stock replenishment based on predictive demand forecasting.

- Barcode scanning and RFID technology for accurate inventory tracking.

- Integration with procurement and sales systems for smooth order fulfillment.

- Advanced analytics and reporting to optimize stock movement and order processing.

Businesses use inventory management software to monitor stock movements, track sales patterns, and forecast demand accurately. It helps maintain optimal stock levels by automating replenishment processes, thereby preventing stock shortages or surplus inventory. Whether managing a small warehouse or a large supply chain, the right inventory software management system enhances efficiency and boosts profitability.

Steps in Inventory Management

- Stock Assessment and Planning – Businesses must analyze sales data, market trends, and historical inventory records to plan inventory levels effectively. This involves forecasting demand, identifying fast-moving and slow-moving products, and determining optimal reorder points to ensure smooth operations.

- Procurement and Supplier Management – Choosing reliable suppliers and managing procurement processes ensure steady stock replenishment. Establishing supplier relationships, negotiating pricing, and setting up automated purchase orders help maintain an uninterrupted supply chain.

- Storage and Warehouse Organization – Proper storage techniques, barcode scanning, and automated tracking help maintain organized warehouses. Implementing shelving strategies, climate-controlled storage, and efficient labeling prevents damage and misplacement of inventory.

- Inventory Tracking and Monitoring – Using RFID, barcode systems, and cloud-based tracking tools ensures real-time visibility of stock levels. Businesses can monitor product movement, minimize losses, and streamline warehouse operations with automated tracking systems.

- Stock Replenishment Strategies – Businesses use demand forecasting, Just-in-Time (JIT) inventory, and automated reordering to optimize replenishment. These methods help reduce holding costs, prevent stock shortages, and maintain a lean inventory structure.

- Auditing and Reporting – Regular inventory audits and performance reports help identify discrepancies and enhance operational efficiency. Conducting cycle counts, inventory reconciliations, and utilizing AI-driven reporting tools ensures accurate inventory records.

Functions of Inventory Management Software

- Automated Inventory Tracking – Reduces human errors and provides real-time updates on stock movements. Businesses can monitor stock levels, track order statuses, and generate accurate inventory reports without manual intervention.

- Order Management – Streamlines order processing, fulfillment, and returns management. The software ensures smooth coordination between sales, procurement, and warehouse teams to optimize the supply chain.

- Multi-Location Inventory Management – Enables businesses to track inventory across multiple warehouses and store locations. Centralized inventory tracking helps avoid stock discrepancies, improves resource allocation, and enhances warehouse efficiency.

- Barcode and RFID Integration – Improves stock accuracy and speeds up warehouse operations. Scanning barcodes or RFID tags reduces picking errors, increases inventory accuracy, and accelerates order fulfillment.

- Stock Alerts and Notifications – Send alerts for low stock, expiring products, and high-demand items. Automated alerts help businesses take proactive measures to replenish stock and prevent order delays.

- Reporting and Analytics – Generate detailed reports on sales trends, stock performance, and inventory turnover. Businesses can use these insights to optimize procurement, adjust pricing strategies, and improve demand forecasting.

- Supplier and Purchase Order Management – Enhances supplier relationships and automates purchase order creation. The software streamlines procurement workflows, tracks purchase history, and manages supplier performance metrics.

- Integration with Business Systems – Seamlessly integrates with accounting, ERP, and e-commerce platforms. Connecting inventory management software with other business tools ensures smooth data flow, improves financial tracking, and enhances overall business operations.

Why Do You Need Inventory Management Software?

- Eliminates Manual Errors – Manual inventory tracking often leads to data entry mistakes, stock miscalculations, and inaccurate reporting. Inventory management software automates stock tracking and order processing, reducing human errors and ensuring more precise inventory control.

- Enhances Operational Efficiency – Automating inventory processes eliminates time-consuming manual work, allowing businesses to allocate resources more effectively. Employees can focus on strategic decision-making and customer service rather than tracking stock manually.

- Reduces Costs and Waste – Overstocking ties up capital and leads to storage expenses, while understocking results in missed sales opportunities. Inventory management software helps balance inventory levels, reducing excess stock and minimizing waste.

- Improves Customer Satisfaction – Ensuring that products are available when needed improves customer trust and loyalty. Real-time inventory updates enable faster order fulfillment, reducing delays and backorders.

- Supports Business Scalability – As businesses grow, so do their inventory management needs. Scalable inventory software allows businesses to expand operations, manage multiple warehouses, and integrate with additional sales channels without disruption.

Choosing the Right Inventory Management System

- Real-Time Inventory Tracking – A good inventory management system provides real-time stock updates, helping businesses avoid shortages and excess stock. This feature enables businesses to respond quickly to demand changes and restock efficiently.

- Automation Features – The software should offer automated stock updates, order fulfillment, and low-stock alerts. Automation improves accuracy, speeds up order processing, and reduces the workload on employees.

- Scalability – As business operations expand, inventory software should be able to handle increasing inventory volumes and support multi-location tracking. The right system grows with the business without requiring frequent upgrades.

- Cloud-Based Access – Cloud-based inventory management systems provide remote access to inventory data, ensuring that teams can track stock levels from anywhere. This feature is particularly beneficial for businesses with multiple locations or e-commerce operations.

- Integration Capabilities – The software should integrate seamlessly with ERP, accounting, and e-commerce platforms to create a unified business management system. Proper integration helps in synchronizing stock levels with sales and financial records.

- User-Friendly Interface – The system should be intuitive and easy to use to minimize training time for employees. A simple, well-designed interface ensures that businesses can efficiently manage inventory without technical difficulties.

How Cflow Automates Inventory Management?

Cflow offers an advanced workflow automation solution that enhances inventory management with the following features:

- Automated Stock Tracking – Eliminates manual updates and ensures inventory accuracy. The system continuously tracks stock levels, automatically updating as orders are placed and shipments are received, reducing human error and increasing efficiency.

- Customizable Workflows – Allows businesses to set up inventory approval workflows. Companies can create automated approval processes for procurement, stock replenishment, and order fulfillment, ensuring a smooth operation without bottlenecks.

- Cloud-Based Integration – Provides real-time access to inventory data from any location. Cloud-based functionality enables businesses to manage stock levels remotely, ensuring seamless synchronization across multiple warehouses or store locations.

- Approval and Procurement Automation – Streamlines purchase approvals and supplier management. Cflow helps automate procurement workflows by enabling real-time tracking of purchase requests, supplier approvals, and order processing.

- Data Analytics and Reporting – Offers insights into inventory trends and performance optimization. Businesses can generate customized reports, analyze stock turnover rates, and identify areas for cost savings through advanced analytics tools.

- Centralized Data Management – Ensures all inventory-related information is stored in a single platform. This eliminates data silos, enabling departments to work collaboratively with accurate and up-to-date stock information.

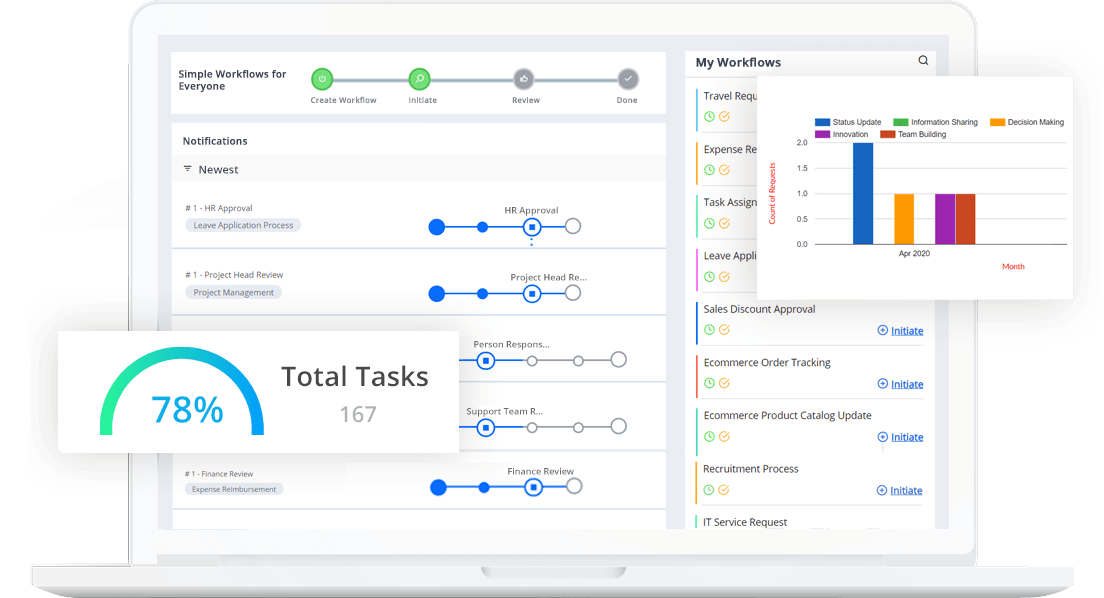

- Intuitive Dashboard – Provides a user-friendly interface with real-time stock insights. The dashboard allows users to monitor key inventory metrics, view stock alerts, and track order statuses in one centralized view, making inventory management effortless and efficient.

- Automated Alerts and Notifications – Send real-time notifications for low stock, expiring products, or discrepancies in inventory. Businesses can take proactive measures to prevent stockouts and reduce wastage.

- Seamless Integration with Business Tools – Cflow integrates with ERP, CRM, and e-commerce platforms, ensuring smooth data flow and enhancing overall business productivity.

- Scalability for Growing Businesses – Whether managing a single warehouse or multiple locations, Cflow scales to accommodate growing inventory needs, making it an ideal solution for businesses of all sizes.

By leveraging these features, Cflow enhances inventory management, improves operational efficiency, and helps businesses stay competitive in an evolving market landscape.

Advantages of Automating Inventory Management

- Enhanced Accuracy – Automating inventory management eliminates human errors associated with manual stock calculations. Barcode scanning, RFID technology, and AI-driven inventory tracking provide real-time stock updates, ensuring data accuracy. This reduces discrepancies and prevents costly stock mismanagement.

- Improved Efficiency – Automating repetitive tasks such as stock counting, order processing, and replenishment requests significantly improves efficiency. Employees no longer need to spend hours manually tracking inventory, allowing them to focus on strategic operations such as demand planning and supplier negotiations.

- Cost Reduction – Automation reduces financial losses caused by overstocking, understocking, and stock discrepancies. By maintaining optimal inventory levels, businesses can minimize waste, lower storage costs, and prevent dead stock accumulation. Additionally, automation reduces labor costs by streamlining warehouse management operations.

- Better Forecasting – AI-driven analytics help businesses make data-informed decisions regarding inventory demand. By analyzing historical sales data, market trends, and seasonal fluctuations, automated inventory systems can accurately predict demand levels, ensuring businesses order the right quantity at the right time. This prevents shortages and improves overall supply chain stability.

- Seamless Integration – Automated inventory management software integrates with ERP, CRM, e-commerce platforms, and accounting software to create a cohesive business ecosystem. Integration eliminates data silos, streamlines inventory reporting, and ensures all departments operate with synchronized data.

- Centralized Inventory Visibility – With cloud-based inventory systems, businesses gain a comprehensive view of their stock across multiple locations. Warehouse managers can track inventory movement, monitor stock levels, and oversee order fulfillment processes from a single interface, improving coordination and efficiency.

- Faster Order Fulfillment – Automation enables businesses to speed up order processing and delivery. When an order is placed, the system automatically updates stock levels, generates invoices, and communicates with shipping providers to ensure seamless fulfillment, leading to higher customer satisfaction.

- Automated Stock Replenishment – Inventory automation allows businesses to set up low-stock alerts and auto-replenishment orders. The system triggers purchase orders when stock reaches predefined thresholds, ensuring uninterrupted supply and reducing the risk of stockouts.

- Regulatory Compliance and Auditing – Automated inventory systems help businesses maintain compliance with industry regulations by generating accurate inventory records and audit trails. This ensures businesses adhere to safety, tax, and reporting requirements without manual intervention.

- Scalability and Adaptability – As businesses expand, automated inventory management solutions can scale accordingly. Whether managing additional warehouses, integrating new sales channels, or handling higher order volumes, automated systems provide the flexibility needed for business growth.

By leveraging automation in inventory management, businesses can optimize stock control, improve operational efficiency, and gain a competitive edge in the market.

End-to-end workflow automation

Build fully-customizable, no code process workflows in a jiffy.

Top 5 Inventory Management Software

- Cflow – The Ultimate Inventory Automation Solution

Cflow stands out as a top inventory management software designed to automate and streamline inventory processes. Its intuitive cloud-based interface provides businesses with real-time inventory tracking, automated stock replenishment, and workflow automation. With AI-driven analytics and seamless integration with ERP and CRM systems, Cflow enhances operational efficiency and decision-making.

Key Features:- Automated stock tracking and replenishment

- Customizable workflow automation

- Cloud-based data access for real-time updates

- AI-powered analytics and reporting

- Seamless integration with third-party business applications

- Zoho Inventory – Best for Small to Medium-Sized Businesses

Zoho Inventory is an easy-to-use inventory management software that helps small and mid-sized businesses manage their stock levels, track shipments, and automate order fulfillment. It integrates well with e-commerce platforms like Shopify, Amazon, and eBay.

Key Features:- Multi-channel inventory management

- Barcode scanning for stock tracking

- Integration with accounting and CRM tools

- Automated order management and invoicing

- Real-time reporting and analytics

- TradeGecko (QuickBooks Commerce) – Best for Wholesale and B2B Companies

TradeGecko, now known as QuickBooks Commerce, is a robust inventory management solution tailored for wholesalers and B2B businesses. It offers multi-location inventory tracking and integrates directly with QuickBooks for financial management.

Key Features:- Advanced order management and B2B e-commerce integration

- Multi-location inventory tracking

- Demand forecasting and reporting tools

- Seamless QuickBooks accounting integration

- Automated purchase order creation

- NetSuite ERP – Best for Large Enterprises

NetSuite ERP is a comprehensive cloud-based inventory and enterprise resource planning (ERP) software designed for large businesses. It offers high-level inventory tracking, automated procurement, and demand planning capabilities.

Key Features:

- End-to-end supply chain management

- Real-time inventory tracking across multiple warehouses

- Automated demand forecasting

- Integration with financial and accounting systems

- Cloud-based scalability for enterprise operations

- Cin7 – Best for Retail and Omnichannel Businesses

Cin7 is an advanced inventory management platform designed for retailers and omnichannel businesses. It provides seamless inventory tracking across multiple sales channels, including in-store, online, and warehouse operations.

Key Features:

- Omnichannel inventory management

- Automated order fulfillment and stock updates

- POS and e-commerce platform integration

- Customizable workflows and reporting tools

- AI-driven demand planning

Choosing the right inventory management software depends on the specific needs of your business. Whether you require automation, scalability, multi-channel support, or enterprise-level control, these software solutions provide a range of features to optimize inventory processes.

Latest Trends in Inventory Management

- AI-powered forecasting – Enhances demand prediction and stock optimization.

- IoT for Inventory Tracking – Smart sensors improve real-time stock monitoring.

- Blockchain for Supply Chain Transparency – Ensures secure and verifiable inventory records.

- Sustainable Inventory Practices – Businesses focus on eco-friendly stock management.

Wrapping Up

Implementing inventory management software is crucial for businesses looking to improve efficiency, reduce costs, and optimize stock control. By automating key inventory processes, businesses can reduce manual errors, enhance accuracy, and streamline operations. Real-time inventory tracking, automated stock replenishment, and integration with business systems ensure that companies can operate more effectively and meet customer demands promptly.

Cflow provides a comprehensive automation solution tailored to enhance inventory management. With features such as cloud-based access, customizable workflows, centralized data visibility, and AI-driven analytics, Cflow empowers businesses to maintain optimal stock levels, prevent losses, and maximize productivity. Whether managing a single warehouse or a multi-location enterprise, Cflow scales with your business needs, ensuring seamless operations and improved profitability.

Invest in Cflow to streamline your inventory operations, enhance decision-making, and stay ahead in a competitive market. With its powerful automation capabilities, Cflow simplifies inventory management, reduces workload, and provides businesses with the tools they need to optimize their supply chain efficiently. Don’t let outdated inventory processes hold your business back—embrace automation with Cflow today.

FAQs

- What is inventory management software?

A system that helps businesses track, store, and manage inventory efficiently. - Why is inventory software management important?

It reduces errors, improves stock tracking, and enhances order fulfillment. - How does inventory mgmt software benefit businesses?

It automates stock control, optimizes workflows, and improves efficiency. - What are the key features of the best inventory management software?

Real-time tracking, automation, integration, and reporting tools. - How does Cflow enhance inventory management?

Cflow automates stock tracking, workflow approvals, and data analytics for better inventory control.

What should you do next?

Thanks for reading till the end. Here are 3 ways we can help you automate your business:

Do better workflow automation with Cflow

Create workflows with multiple steps, parallel reviewals. auto approvals, public forms, etc. to save time and cost.

Talk to a workflow expert

Get a 30-min. free consultation with our Workflow expert to optimize your daily tasks.

Get smarter with our workflow resources

Explore our workflow automation blogs, ebooks, and other resources to master workflow automation.

What would you like to do next?

Automate your workflows with our Cflow experts.