Exploring the Synergetic Relationship between Sourcing and Procurement

Key takeaways

- Sourcing vs. procurement is a synergetic relationship.

- The sourcing process involves outlining the sourcing category, supply market research, developing a sourcing strategy, deciding on bids and request proposals, negotiation, confirmation with the selected suppliers and finally benchmarking.

- The procurement process involves the sourcing stage, purchasing stage, and payment stage.

- Sourcing and procurement differ in terms of total cost of ownership, discount rates, supplier network, vendor relationships, and failure approaches.

- Both sourcing and procurement are crucial for business – they work together to enhance a company’s profit, generate and utilize data for purchasing projects within the stipulated budget, and help companies with strategic decisions.

- With technological advancements such as AI, the use of automated procurement/sourcing software is gaining momentum as more and more companies are utilizing it.

When purchasing goods and services for an organization, the terms sourcing and procurement are often used interchangeably.

Scouring is a subset of procurement and large organizations have separate departments dealing with each of these processes. Both sourcing and procurement focus on minimizing costs and risks in purchasing and maximizing business ROI. therefore, it is essential to understand their similarities and differences to leverage their mutual benefits.

Table of Contents

What is Sourcing?

Sourcing can be defined as finding suitable suppliers to provide the products you need at the expected margins. Sourcing is the first step of a company’s supply chain. Having strategic sourcing can help you achieve balance and be a real game-changer. But for many, sourcing has become another word for procurement until it becomes strategic and a peripheral corporate function.

Since the 1990s, large companies began to develop highly sophisticated procurement departments which are managed by corporate finances. These procurement departments began to initiate comprehensive agreements with vendors, which significantly impacted the organization’s growth. Traditional sourcing gradually evolved into strategic sourcing owing to its dynamic nature.

The difference between conventional and strategic sourcing is that cost has become the significant and only component of the corporate hierarchy needed in strategic sourcing. Therefore, other elements such as regulatory compliance, service, quality, innovation, and supply assurance became impossible to sacrifice for lower prices.

With rapid globalization in association with technological innovation, the essence of competition is changing. Moreover, outsourcing is becoming more and more sophisticated, and even core functions such as engineering, manufacturing, and marketing are often outsourced.

This changes the way a firm thinks about its value chain and its position among its competitors. Companies that are progressive are making their value chains more elastic, making their firms more flexible and open to new opportunities. Therefore, strategic sourcing is being transformed into capability sourcing in some cases.

Example of sourcing: Sourcing can be done locally and globally. One example of insourcing is FedEx, which successfully plans and manages inbound transportation for more than 1500 product suppliers.

The revenue generated is invested in purchasing 26 General Motor powertrain facilities. This puts FedEx to be a leading logistic outsourcing company with a value of 225 billion U.S. dollars. Another example of sourcing is when Starbucks outsources to get its raw materials for coffee from its headquarters country and countries such as Guatemala and Colombia.

Steps Involved in Sourcing Process

There are several steps in the sourcing process. They are as follows:

- The first step is to outline the souring category, including the volumes, spending amounts, current prices, suppliers, and specification details. In addition to this, the type of users, departments involved in the supply chain, and users’ locations are analyzed.

- In this step, it is necessary to do supply market research and understand the buying power based on the sourcing strategy. Many of the companies use Kraljic’s matrix for segmenting vendor bases. The sourcing strategy is devised by mapping the supply chain using two critical dimensions: risk and profitability.

- The third step is to develop the sourcing strategy. In this step, the sourcing team decides from whom to buy with reduced cost and with minimal risks. Here, the strategy is discussed with stakeholders to choose alternative suppliers based on the market competition.

- Upon developing the strategy, the business now decides on bids and requests proposals from potential vendors. The product specifications and service requirements should comply with the company’s needs. This should include price breakdowns, legal and financial terms, and conditions.

- In this step, the sourcing team begins negotiation to place valid bids to the chosen supplier. It is necessary to shortlist a handful of vendors and conduct multiple rounds of negotiation before approving them.

- In this step, the suppliers are notified of their confirmation, and the implementation process begins. Any improvements and changes in the service requirements will also be made.

- This is the final step of the sourcing process, where the continuous cycle of benchmarking the status of the products and monitoring the results is done. When the target is achieved, the business then goes back to step 1 and restarts the sourcing process again.

What is Procurement?

Procurement can be defined as the process that involves every activity from obtaining the necessary goods and services from the suppliers needed for a company’s day-to-day activities. The process includes sourcing, negotiation, purchasing, inspecting, and maintaining records.

Example of the procurement: when a company needs a new service such as an email security solution, the procurement process helps to pick the best supplier for providing this service at a reasonable price. Another example of procurement includes purchasing raw materials, machinery parts, and items for a manufacturing company.

Procurement Process

The procurement process is unique to each organization, and it generally starts with identifying the requirement. The creation of a purchase order follows this as per the business specifics. Upon selecting the approved vendors, the purchase order will be sent for further approval to the finance or procurement team. If approved, the purchase order becomes a purchase requisition. If rejected, it will be sent back to the respective team with the reason for rejection. Once the purchase items are received, the items are checked for quality, and the finance department accounts for payment.

With this said, the procurement process can also be thought of as a three-stage process.

- The first stage is the sourcing stage, where the initial steps of identifying a company’s needs, creating purchase requests, and sending them to potential vendors are completed. This stage is the foundation for the procurement process as it helps to establish grounds with the suppliers and develop trust in the vendor relationship.

- The second stage is the purchasing stage. In this stage, the procurement team begins the negotiation process and does the quality check for the purchased items from the vendor.

- The third stage is the payment stage. This is the final stage where all the financial transactions are monitored.

The accounts payable is generally done as a three-way process to ensure safety as well as invoice accuracy. Upon approving the invoice, the concerned departments make the payments, and records of invoices and payments are maintained carefully.

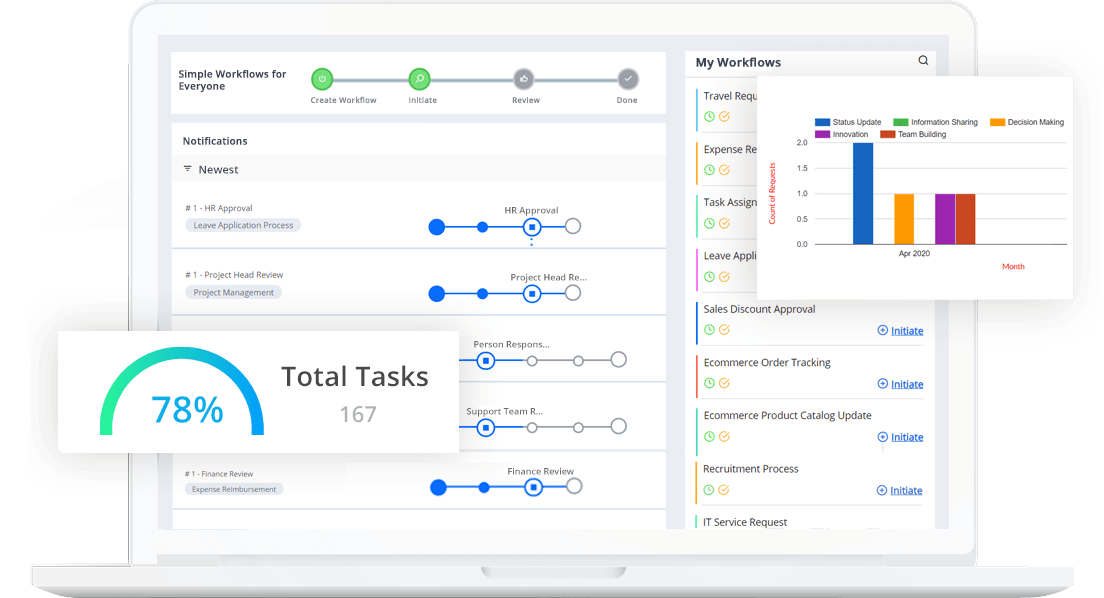

End-to-end workflow automation

Build fully-customizable, no code process workflows in a jiffy.

The Key Differences Between Sourcing and Procurement

| Sourcing | Procurement |

|---|---|

| The total cost of ownership can be made at the best possible price | The cost per unit can be done at the lowest possible value |

| The highest possible quality products can be obtained at the lowest possible cost | Mass discounts are obtained for generating products at high volumes |

| Global supplier network location | Local supplier base location |

| The relationship between the vendor and the organization is sustainable and intense. | The relationship between the vendor and organization is developed based on acquaintanceship |

| The performance of the supplier is lean and efficient as it focuses mainly on achieving effectual output from minimum input | The version of the supplier is effective as it focuses primarily on completing the specified activities and achieving goals |

| The skills needed for effective sourcing include cross-functional skills, collaborating, mutual respect, problem-solving and self-negotiating, and making compromises whenever necessary | The skills required for an effective procurement process has analytical and negotiation skills. |

| The process involves requesting and comparing the best quality and cost-effective services. | The process involves what and from whom to buy the necessary products. |

| Any failure happens handled using proactive approaches | Any loss occurring in the process is dealt with using reactive strategies |

Where do Sourcing and Procurement Meet?

Both sourcing and procurement are crucial for business, and the shared data is their rendezvous point. Together they ensure that the business stays away from risks to attain stability and sustainability over time. They work together to enhance the company’s profit. The sourcing team helps maintain and analyze the generated data; the procurement team uses this data to provide products within the stipulated budget.

Upon completion of the process cycle, the procurement team generates data and sends it to the sourcing team for managing supplier relationships. This process includes assessing the supplier’s performance, which helps the company make strategic decisions. This informed decision helps in maximizing the company’s value.

Moreover, the automation provides access to the data across different platforms and supplier bases, reducing lags and delays. The collaboration between sourcing and procurement can enhance the supply chain by enabling uninterrupted supply and effective long-term planning.

Importance of Learning the Difference

Why is it vital to know the difference between sourcing and procurement? Some Procurement managers think that sourcing and procurement are the same. This makes them fail in incorporating sourcing in procurement successfully. So, when you learn the difference, having a proper sourcing strategy can save your company both time and money. An appropriate sourcing strategy helps you identify potential suppliers before beginning the procurement process.

In places where there is a need for automation and the procurement manager fails to recognize the differences, it will limit the full use of your company’s automated procurement program. This has a considerable impact on the company’s procurement and sourcing activities.

Furthermore, knowing the difference is a basic knowledge that a procurement manager should possess. Understanding this difference will also help the procurement managers with the vendors and suppliers during the negotiation phase. This makes them help pick the best suppliers at the best prices.

Use of Extensive Procurement/Sourcing Software

The use of procurement/sourcing software is gaining momentum as more and more companies are utilizing it. Statistical reports show that the market for procurement software is expected to increase by 10.2% by 2026. A report from ResearchandMarkets.com predicts that the global procurement software market to have a revenue of $9.65 billion by 2026. The sourcing software market is expected to increase by 7.4% by 2026.

The need for strong procurement software is increasing with the increase in workflow automation. Especially with the integration of artificial intelligence, procurement software creates new opportunities to work with. Likewise, the demand for good sourcing software has increased with the changes in consumers’ buying patterns in the last few years. Businesses need to adopt sourcing software and tools to implement procurement efficiently using new cloud computing technologies, artificial intelligence, and the Internet of Things (IoT).

With the growing need for these tools, they should offer the businesses certain features such as vendor database with rankings, budgeting, automated request for quotes (RFQs), collaborative data access, security checks, cross-referenced storage in the database, generation, and management of purchase requisitions and purchase orders, transactional procure-to-pay processes.

The collaboration between sourcing and procurement, along with technological automation, can drastically improve the effectiveness of the company. When they work together from the pooled data, the benefits are innumerable as it helps improve supplier relationships and enables strategies to maximize value. Therefore, every business needs powerful workflow automation software like Cflow.

Cflow is an all-in-one workflow automation software that helps to automate your business. It is a no-code BPM and a cloud-based software specially designed to enhance your company’s efficiency. It is ideally suitable for all organizational sizes, especially for small and medium-sized enterprises. It has a wide range of features ideal for almost all kinds of industries, from finance to construction and healthcare to marketing.

You can easily use Cflow by hosting it on your servers with several APIs for easy third-party integrations. It has several other features, such as setting up your automation rules, customizable dashboards, reports, and data analytics. Cflow offers a powerful data encryption feature to store your data safely in the cloud. know more and signup for a free demo today.

Key takeaways

As the supply chain becomes more and more sophisticated, businesses continue to adopt and strengthen their sourcing and procurement strategies. Therefore, knowing the difference between the two and acknowledging the symbiotic relationship between sourcing and procurement can apparently help you to reinforce your company’s overall supply chain. This, in turn, directly influences the company’s growth.

Moreover, AI-powered cloud-based software and tools will help a company to automate its business processes. It will also increase the company’s agility. With technological advancement, it is essential to know the difference between sourcing and procurement to utilize their individual potential to the maximum. In addition, automation in your workflows can accelerate the execution speed of your organization’s supply chains, which gives you a competitive edge.

What should you do next?

Thanks for reading till the end. Here are 3 ways we can help you automate your business:

Do better workflow automation with Cflow

Create workflows with multiple steps, parallel reviewals. auto approvals, public forms, etc. to save time and cost.

Talk to a workflow expert

Get a 30-min. free consultation with our Workflow expert to optimize your daily tasks.

Get smarter with our workflow resources

Explore our workflow automation blogs, ebooks, and other resources to master workflow automation.

What would you like to do next?

Automate your workflows with our Cflow experts.