How to Identify and Eliminate the 8 Wastes of Lean in Your Workflow

Key takeaways

- The 8 wastes of Lean represent key inefficiencies that, if unaddressed, can significantly hinder a business’s productivity and profitability.

- By eliminating these wastes, companies can achieve higher operational efficiency, reduce unnecessary costs, and ultimately enhance customer satisfaction.

- Proven tools like Kanban, 5S, and workflow automation provide practical strategies to identify and tackle these inefficiencies effectively.

- Real-world examples from sectors like manufacturing, healthcare, and IT show that Lean principles can lead to substantial process improvements and cost savings.

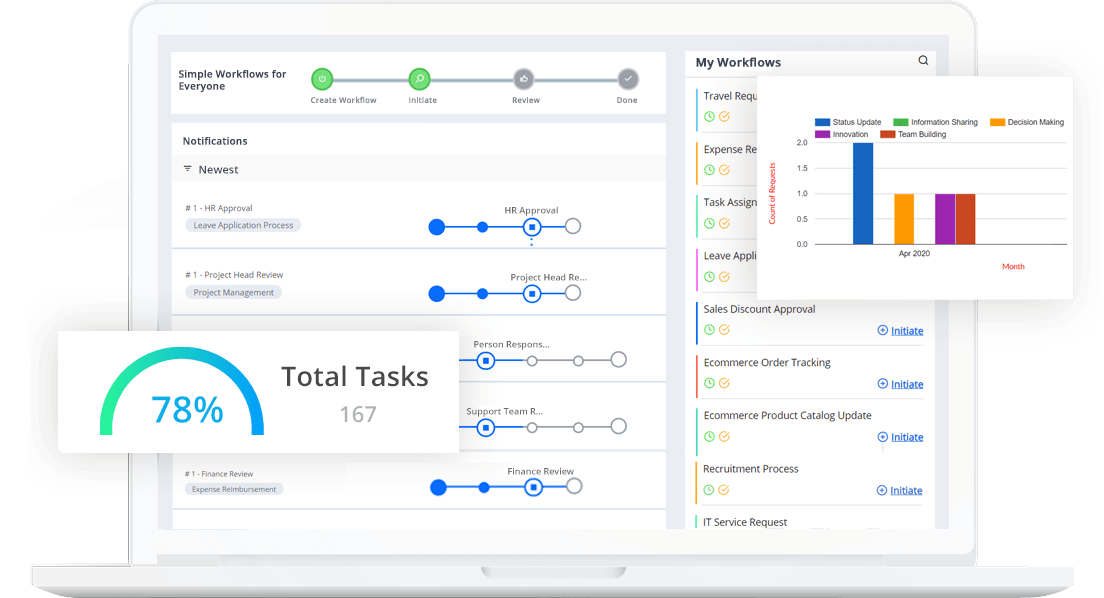

- Automation platforms, such as Cflow, simplify the process of identifying and eliminating waste, creating more streamlined workflows and fostering a culture of continuous improvement.

What are the 8 Wastes of Lean?

The 8 Wastes of Lean, often encapsulated by the acronym “DOWNTIME,” highlight the critical inefficiencies that hinder organizational productivity and profitability. Lean methodology, rooted in the principles of continuous improvement and waste reduction, identifies these wastes as areas where resources—time, effort, or materials—are not used optimally. Each waste represents a specific challenge that can disrupt workflows, increase costs, and impact overall efficiency.

By systematically recognizing and addressing these inefficiencies, organizations can eliminate redundancies, optimize processes, and create more value for customers.

Here is a detailed breakdown:

The 8 wastes of lean manufacturing, which highlight key areas where efficiency can be improved within any organization, are as follows:

1. Defects

Defects are the silent killers of productivity. They range from small errors, like incorrect data entries, to major flaws that cause products to fail or services to fall short of expectations. Every defect incurs rework, increases costs, and can tarnish an organization’s reputation. For instance, a product defect may result in customer returns, while a simple data mistake can lead to a series of erroneous decisions.

To tackle this:

Focus on Quality Control: Implement robust systems at every production stage to identify defects early on.

Root Cause Analysis: Dig deeper into issues using methods like the 5 Whys to uncover underlying causes.

Train Employees: Equip the team with proper training and tools to prevent errors from happening in the first place.

By eliminating defects, businesses can save money, improve customer satisfaction, and build a stronger brand reputation.

2. Overproduction

Have you ever seen a factory with piles of unsold products? Overproduction leads to excess inventory that costs companies money in storage and maintenance. Producing more than needed wastes valuable resources and increases the risk of obsolescence. For example, manufacturing goods in anticipation of a demand that never comes can tie up capital in unsold stock.

To combat overproduction:

Just-in-Time (JIT): Align production with real demand to ensure you’re not producing before it’s necessary.

Accurate Forecasting: Use data to predict actual demand, allowing you to match supply more precisely with customer needs.

Smarter Scheduling: Fine-tune production schedules to reflect real-time orders rather than assumptions.

Reducing overproduction ensures your resources are focused where they are truly needed.

3. Waiting

Waiting can be one of the most frustrating wastes to experience—whether it’s employees waiting for approvals or machinery waiting for parts. Idle time not only decreases productivity but also impacts employee morale. Imagine waiting for a part to arrive while workers sit idle—it doesn’t just waste time, it halts momentum.

To minimize waiting:

Automate Approvals: Use workflow tools that speed up decision-making and reduce waiting times for approvals.

Improve Communication: Ensure teams are well-informed and can access what they need without delays.

Streamline Processes: Remove unnecessary dependencies in workflows that cause hold-ups.

Reducing waiting boosts both productivity and employee satisfaction.

4. Non-Utilized Talent

There’s a hidden power in your team that may not always be tapped into. When employees are underutilized, not only do you lose out on innovation, but they also feel disengaged. Think of a highly skilled worker spending hours on routine tasks that don’t tap into their true potential. That’s wasted talent!

Here’s how to make the most of your team:

Cross-Training: Give employees opportunities to learn new skills and contribute across various roles.

Value Feedback: Encourage employees to share their ideas and implement improvements where possible.

Job Enrichment: Assign more complex tasks that engage employees and use their full skills.

By leveraging the full potential of your workforce, you open the door to greater innovation and engagement.

5. Transportation

When things are constantly moving—whether it’s materials, products, or information—it can be a sign of inefficiency. Every unnecessary movement, whether it’s across warehouses or from one department to another, adds cost, time, and sometimes the risk of damage. If your materials are bouncing around like a pinball, you’re not optimizing your operations.

How to reduce transportation waste:

Optimize Layouts: Design facilities and workflows so that materials don’t need to travel unnecessarily.

Consolidate Routes: Use fewer, more efficient transportation routes to reduce redundant movements.

Digital Information Flow: Instead of transferring physical documents or data, use digital tools to ensure quick and accurate information sharing.

Cutting down on transportation waste saves time and reduces operational costs.

6. Inventory

Excess inventory is a double-edged sword: it costs money to store, maintain, and insure, while also tying up resources that could be used elsewhere. Overstocking or stockpiling unneeded materials means more money spent on storage and the risk of products becoming obsolete before they’re even used.

Ways to manage inventory waste:

Lean Inventory: Adopt pull-based systems (like Kanban) to ensure stock only arrives when it’s needed.

Demand Forecasting: Use technology to predict demand more accurately, reducing the need for excess inventory.

Regular Audits: Frequently review stock levels and make adjustments to avoid overstocking.

By managing inventory more effectively, you free up capital and avoid excess waste.

7. Motion

How often do your employees make unnecessary trips to pick up materials, search for tools, or handle redundant tasks? Excessive motion, whether it’s walking to the wrong workstation or repeatedly accessing the same documents, reduces efficiency and wastes valuable time. Small movements, over time, can add up to a significant loss of productivity.

To minimize motion waste:

Ergonomics: Place tools and materials within easy reach to reduce unnecessary movements.

Workspace Optimization: Design workspaces that enable workers to move and work with ease.

Streamline Digital Workflows: In the digital realm, reduce unnecessary clicks and steps in your software systems to improve efficiency.

Eliminating motion waste creates a more efficient and comfortable working environment.

8. Extra Processing

Extra processing means doing more work than necessary—whether it’s inspecting products more than required, adding features that customers don’t need, or using more resources than required. This waste directly impacts your bottom line by increasing costs and diverting attention from higher-priority tasks.

To reduce extra processing:

Simplify Processes: Focus on value-adding activities and eliminate redundant steps in production.

Standardize Work: Create clear and standardized work procedures to ensure consistency and eliminate unnecessary effort.

Customer-Centric Design: Only include features and services that meet customer needs, cutting out anything that doesn’t add value.

By focusing only on necessary tasks, you can save resources and enhance product value.

How to Identify the 8 Wastes in Your Organization

Recognizing waste is the first step toward improving efficiency and productivity. By observing processes, analyzing workflows, and engaging employees, organizations can identify inefficiencies and implement targeted improvements.

Gemba Walks

One of the most effective methods for identifying waste is conducting Gemba Walks. This approach involves managers and team members observing processes directly on the ground where the work happens. By doing so, they can pinpoint inefficiencies as they occur. Gemba Walks fosters a deeper understanding of workflow issues and uncovers immediate opportunities for improvement.

Value Stream Mapping

Another invaluable tool is Value Stream Mapping. This technique creates a visual representation of the entire process flow, from start to finish. It highlights bottlenecks, redundancies, and steps that do not add value. Once the map is created, it serves as a roadmap for targeted improvements, enabling organizations to streamline their workflows effectively.

Employee Feedback

Involving employees in waste identification is equally critical. Frontline workers, who are closest to the processes, often have firsthand knowledge of inefficiencies. Engaging them through feedback sessions provides valuable insights and fosters collaboration. Creating an open environment where employees feel encouraged to share their observations can help uncover hidden inefficiencies and drive innovation.

A case study from Daman Products reported significant improvements after adopting Lean-focused strategies, including a 97% reduction in cycle times, 50% decrease in setup times, and a reduction in lead times from 4–8 weeks to 5–10 days.

Tools and Techniques to Eliminate the 8 Wastes in Lean

The U.S. Environmental Protection Agency (EPA) has observed that numerous companies across various sectors are implementing Lean production systems to reduce resource requirements, increase customer responsiveness, and improve product quality.

Effectively addressing the eight wastes requires a structured approach using Lean tools and techniques. These methods help organizations streamline processes, improve efficiency, and create a culture of continuous improvement.

Kaizen: Driving Continuous Improvement

Kaizen, meaning “change for the better,” focuses on small, incremental improvements over time. This approach encourages employees at all levels to actively identify inefficiencies and implement solutions. By making continuous improvement a core practice, organizations can ensure that waste reduction is ongoing rather than a one-time initiative.

5S Methodology: Organizing for Efficiency

The 5S framework—Sort, Set in Order, Shine, Standardize, and Sustain—creates structured, efficient workspaces. Removing unnecessary items (Sort), organizing tools and materials logically (Set in Order), maintaining cleanliness (Shine), setting clear standards (Standardize), and ensuring long-term adherence (Sustain) all contribute to reducing waste. A well-organized workspace minimizes unnecessary movement, improves productivity, and enhances workplace safety.

Kanban: Visualizing and Optimizing Workflow

Kanban is a visual project management tool that helps teams track tasks and workflows in real-time. By displaying work progress on a board, teams can quickly identify bottlenecks, balance workloads, and prevent overproduction or waiting time. This system promotes a smoother, more efficient workflow, ensuring tasks move through the process without unnecessary delays.

Root Cause Analysis: Solving Problems at Their Source

To eliminate waste effectively, organizations must address problems at their root cause. The “5 Whys” technique is a simple yet powerful method for uncovering the deeper issues behind inefficiencies. By repeatedly asking “Why?” until the core problem is identified, businesses can develop targeted, long-term solutions rather than temporary fixes.

Workflow Automation: Reducing Manual Effort

Repetitive manual tasks, such as approvals, data entry, and document processing, can slow down operations and increase the risk of errors. Automation tools like Cflow help organizations streamline these processes, ensuring accuracy, efficiency, and faster task completion. By automating routine workflows, teams can focus on higher-value tasks, improving overall productivity.

How Do Lean Strategies Address the 8 Wastes Across Sectors?

The manifestation of the 8 wastes varies significantly across industries, making it essential to adopt tailored strategies for each sector.

Manufacturing

For example, In manufacturing, overproduction is a common issue, leading to excessive inventory costs and storage challenges. Implementing Just-in-Time (JIT) production systems can help align production with actual demand, reducing waste.

According to studies, companies are increasingly leveraging Lean methodologies to align with sustainability goals, aiming to reduce energy consumption, material waste, and emissions.

Healthcare

Waiting times often impact patient care and overall efficiency. Streamlining patient intake processes and adopting electronic health records can minimize delays and improve service quality.

IT and software development

This industry frequently encounters overprocessing, where unnecessary features are added to products. Employing Agile methodologies can help prioritize customer needs and eliminate redundant development efforts.

Retail

Businesses in this field often face challenges with transportation inefficiencies, such as long supply chain routes and multiple handoffs. Optimizing logistics networks and implementing inventory management systems can reduce these inefficiencies and enhance profitability.

End-to-end workflow automation

Build fully-customizable, no code process workflows in a jiffy.

How to Measure the Success of Waste Reduction Efforts?

Tracking key metrics helps organizations assess progress, refine strategies, and ensure continuous improvement.

- Use Key Performance Indicators (KPIs)

KPIs provide measurable insights into the effectiveness of waste reduction efforts. Tracking relevant metrics ensures organizations stay on course for continuous improvement. - Monitor lead time reduction

Shorter lead times indicate streamlined processes and improved efficiency. A consistent reduction suggests that waste elimination strategies are working effectively. - Track inventory turnover rates

A higher inventory turnover rate signifies reduced excess stock and better demand forecasting. This helps minimize storage costs and prevent obsolete inventory. - Measure error rates

A decline in errors reflects stronger quality control and fewer defects. Lower defect rates lead to improved customer satisfaction and reduced rework costs. - Assess employee satisfaction scores

Engaged employees are more productive and proactive in identifying inefficiencies. Higher satisfaction scores suggest a better work environment and optimal talent utilization. - Conduct regular metric reviews

Frequent analysis of performance metrics helps pinpoint areas requiring additional focus. Reviewing data over time ensures continuous refinement of waste reduction efforts. - Address stagnation in progress

If lead time reduces plateau, workflow automation and bottleneck analysis may be necessary. Identifying new inefficiencies ensures sustained process improvements.

Common Challenges and How to Overcome Them

Implementing new practices often presents obstacles that can hinder progress. Overcoming these challenges requires effective strategies, clear communication, and strong support across all levels of the organization.

Resistance to Change

Resistance from employees and managers can slow Lean adoption. Address this challenge by implementing hands-on training sessions that demonstrate Lean’s real-world benefits. Use success stories from similar organizations to highlight the positive outcomes. Encourage peer learning where employees who have embraced Lean can mentor others.

Securing Leadership Buy-In

Without leadership support, Lean initiatives often struggle to gain momentum. Gather data-driven evidence on how Lean has improved operations in similar industries. Present a clear business case, focusing on cost savings, process efficiency, and long-term gains. Involve leadership early in the process to get their buy-in and ensure they allocate necessary resources.

Integration with Existing Systems

Integrating Lean tools into current workflows can disrupt operations. Start by conducting a comprehensive audit of existing systems to identify integration points. Choose Lean tools and technologies that are designed for easy integration with existing software or processes. Begin with small, low-risk pilots to test compatibility before full-scale implementation.

Future Trends in Lean Waste Management

The landscape of Lean waste management is rapidly evolving with new technologies and shifting work environments.

AI and IoT are now crucial in Lean waste management. These technologies allow real-time monitoring and data analysis, providing businesses with quick insights to spot inefficiencies and make improvements faster. They also help predict potential issues, ensuring continuous optimization.

Sustainability is becoming a key focus. Companies are integrating eco-friendly practices into Lean initiatives by reducing energy consumption, cutting waste, and optimizing resources, aligning operational efficiency with environmental goals.

Hybrid work models are also influencing Lean practices. As remote and distributed workforces grow, businesses must adapt Lean strategies to maintain productivity and minimize waste across decentralized teams. Leveraging remote tools and collaboration technologies will help streamline operations in this new setup.

As these trends continue, businesses must stay adaptable, using technology and sustainable practices to maintain efficiency and long-term success.

Conclusion:

Lean management is a pathway to delivering unparalleled value to customers by optimizing processes and eliminating inefficiencies. With Cflow’s automation-first platform, you can seamlessly integrate Lean principles into your workflows, driving innovation, efficiency, and success at every level.

Transform the way your business operates. Start your free trial with Cflow today and take the first step toward achieving streamlined processes and operational excellence.

FAQs

- What is the Lean concept?

Lean is a methodology aimed at reducing waste, optimizing processes, and delivering maximum value to customers. By focusing on efficiency and continuous improvement, Lean helps businesses streamline workflows and eliminate unnecessary steps. - What are the 8 wastes of Lean?

The 8 wastes, represented by DOWNTIME, include:

- Defects: Errors requiring rework.

- Overproduction: Producing more than needed.

- Waiting: Delays or idle time.

- Non-utilized Talent: Underusing employees’ skills.

- Transportation: Excessive movement of materials.

- Inventory: Holding more stock than required.

- Motion: Unnecessary movements.

- Extra Processing: Doing more work than necessary.

Tackling these wastes is essential for boosting efficiency and cutting costs.

- What is Lean and Waste?

Lean is about maximizing customer value while minimizing waste. Waste includes activities or processes that consume resources but do not add value, such as delays, defects, or overstocking. Lean’s goal is to identify and remove these inefficiencies. - What is 5S in Lean?

5S is a Lean workplace organization tool consisting of:

- Sort: Eliminate unnecessary items.

- Set in Order: Arrange tools for easy access.

- Shine: Keep the workspace clean.

- Standardize: Establish consistent practices.

- Sustain: Maintain discipline and regularity.

5S ensures a safe, productive, and organized work environment.

5. What is the full form of Lean?

Lean isn’t an acronym; it refers to a methodology focused on reducing waste and improving efficiency to maximize value for customers.

What should you do next?

Thanks for reading till the end. Here are 3 ways we can help you automate your business:

Do better workflow automation with Cflow

Create workflows with multiple steps, parallel reviewals. auto approvals, public forms, etc. to save time and cost.

Talk to a workflow expert

Get a 30-min. free consultation with our Workflow expert to optimize your daily tasks.

Get smarter with our workflow resources

Explore our workflow automation blogs, ebooks, and other resources to master workflow automation.

What would you like to do next?

Automate your workflows with our Cflow experts.